JFTs engineering-led manufacturing capability turns ideas into hardware by providing a full-service machine and fabrication shop to build the products designed by both JFT and our customers. This capability is housed in the same building as our engineering team making collaboration and design change efficient which is required for our customer mission critical component needs.

Welding

- Full-service weld capability

- AWS D1.1 and D1.6

- Certified Weld Inspector

- VT/LPT/MPT (ASNT-TC-1A)

- RT

- Complex Stainless Steel Structures

- ASME U and R Stamp

- Process Vessels

- Rolling Capability

- B31.3 pipe welding and inspection

Machining Services

- CNC 4-Axis Milling

- CNC Dual Axis Lathe with live tooling and bar feeder

- Manual Mill

- Manual Lathe

- Post weld machining

- Prototype and production run capability

- Digital CMM

- Laser tracker

Plate Processing

- CNC Waterjet Cutting Table

- CNC Hydraulic Press Brake

- Rolling capability

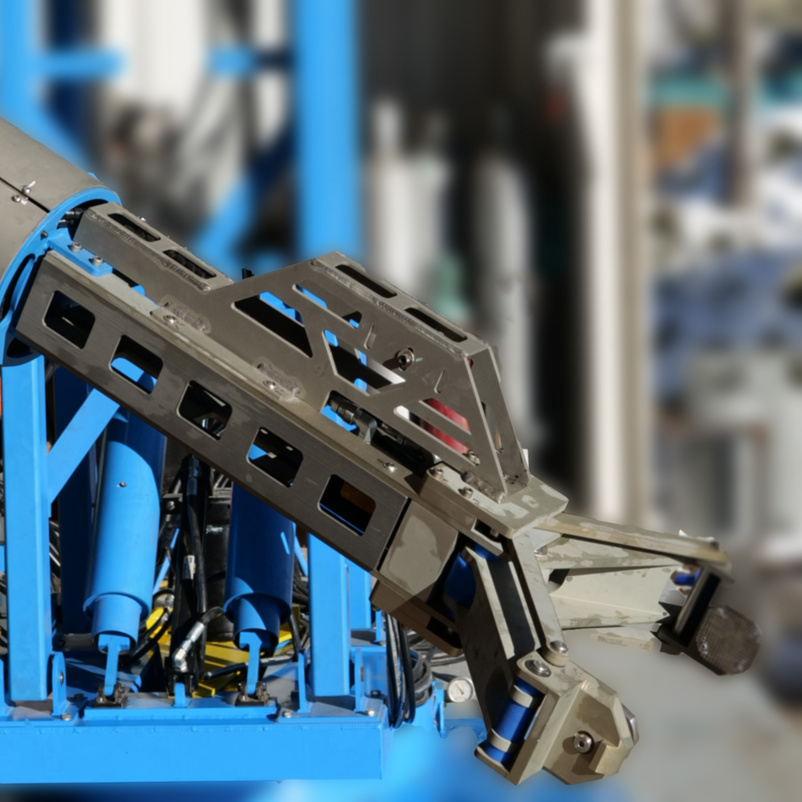

Hydraulic Systems

- Hose routing

- Custom hose manufacture

- Integration of power units

Control Panel Fabrication

- Integration of UL508A control panels

- Wiring and integration

- Instrumentation and controls integration

Process Systems

- B31.3 pipe welding and inspection

- Ventilation Skids

- Piping Skids

- Vacuum systems

- Heat Exchanger integration

Plastic Welding

- Plastic Welding program compliant to AWS B2.4

- Certified Welders and Inspectors

- PVDF

- Tank Welding

- Pipe Welding

- Pressure Testing

- Kynar (PVDF)

- Polypropylene (PP)

- High-Density Polyethylene (HDPE)

- Polyvinylchloride (PVC)

Contact us